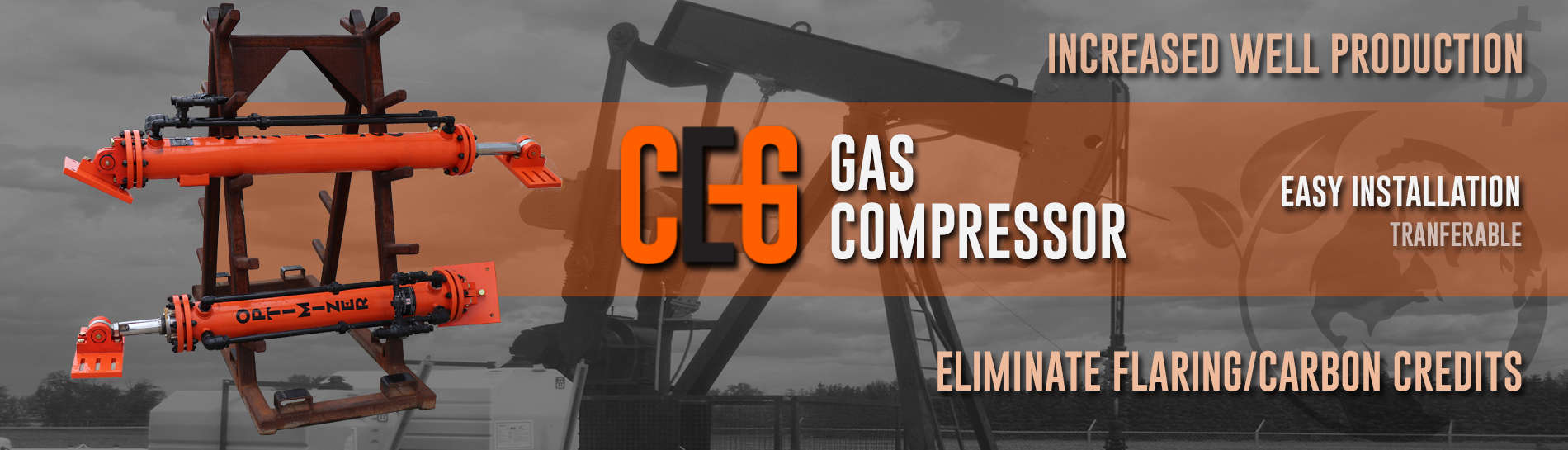

IMPROVING OIL AND GAS PRODUCTION WITH THE BEAM MOUNTED GAS COMPRESSOR

The main function of the Beam Mounted gas Compressor (B.M.G.C.) single acting or double acting is to draw gas from the casing side of the well and to discharge the gas into the flow line. By doing so, the B.M.G.C. actually reduces the backpressure on the formation face, thus allowing additional oil to enter the well bore.

BEAM MOUNTED COMPRESSOR THEORY:

If a well is not pumped off, a column of fluid will exist above the formation. The fluid exerts backpressure on the formation in the form of hydrostatic head and in addition to the hydrostatic head of the fluid level, the surface casing pressure exerts backpressure on the formation. Therefore, it could be inferred that an increase in the back pressure on the formation will cause a decline in the draw-down and correspondingly reduce the productivity of the well. With the decrease of casing pressure, the ability for a well to increase production is greater.

Also, if the casing pressure is high in relation to the bottom hole pressure, some of the free gas enters into the pump barrel causing gas locks and reducing the pump volumetric efficiency. By reducing the casing pressure on wells with low bottom hole pressures, we minimize the gas volumes entering the pump barrel and thus reduce gas lock problems in the pump. The free gas is diverted into the annulus and produced with the assistance of the B.M.G.C.

In addition, if the gas is allowed or forced to enter the annulus and mix with the annulus fluid, the density of the fluid is reduced. A reduction in the fluid level density translates into a reduction of back pressure exerted on the formation by the hydrostatic head of the annulus fluid column, and also translates into increased oil and gas production.

When selecting wells for B.M.G.C. applications, look for high casing pressure, low bottom hole pressure, size and condition of pumping unit, production rate and trend, and G.O.R.

Wells with very little solution gas respond very well to annulus gas compression. Wells that have lost production after flow lines were put into place are possible candidates for B.M.G.C.

SOLUTION:

The B.M.G.C. demonstrates its ability as a low cost and efficient portable gas compressor because of its applicability and its mobility. It carries out its designed function of lowering casing pressure and increasing oil and gas production.

In addition, because the gas is being compressed into the flow line, a purging effect will take place on fluids in the flow line.

OTHER APPLICATIONS:

- Boosting gas production from wells with lower pressures than gathering system.

- Eliminating high propane costs for fuel gas and instrument gas.